Filter Types Used in Dust Collection

Dust collectors with filters inside have various applications for cleaning dust from air and gas fluids with its potential performance.

The basic form of filter dust collectors is a large compartment containing similar filter equipment. These equipment are also mounted vertically on the support plate that divides the compartment into two parts.

We can examine these filters in two main groups as cloth (bag) and cartridge filters. The most common element form in a cloth filter has a basically cylindrical piece of filter material; both ends enclosed in the support cage or sealed from the bottom and sealed with the top support plate.

Cartridge filter is a piece of tubular filtration equipment that can be used in a variety of industries for a range of filtration needs. The cartridge is housed in a housing or housing and is used to remove unwanted particles, contaminants and chemicals from liquids. As the cartridge flows through the housing and through the filter element, it is exposed to water, liquid or solvent that must be filtered. Cartridge filters can also remove submicron particles.

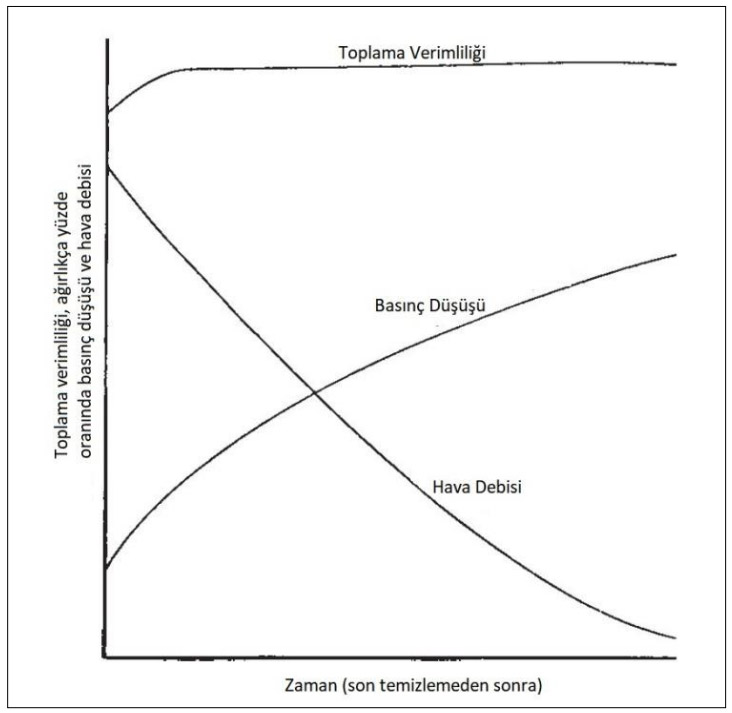

Filtration efficiency is not a fixed parameter in filters. The efficiency increases and the permeability decreases due to the cake effect during service and is normally higher than after use and cleaning. Fabric selection is therefore essentially a compromise between efficiency, cleanability and permeability. The performance characteristics of a filter normally follow the curve types shown in Figure 3.

No filter dust collector can be made 100% efficient, but with proper material selection, adequate sizing and good design, a dust collector can operate at efficiencies exceeding 99%. The endpoint of a usage cycle when the filter needs to be cleaned is when the resistance to flow causes the airflow to drop below an acceptable minimum. A filter can be operated continuously with individual element cleaning.